Top Secret: American Chess Table- Prepping the parts

If you have seen my blog entry for the American chess board, you will understand the need for the next project! The American chess table will go under the chess board to provide storage for the chess pieces, and to allow a comfortable method to play a game. In keeping with the theme of the chess board, we used only American maple for the legs, rails and drawers. The legs were turned and processed on Don Russell’s XYZ axis machine. The legs have been hanging around the shop for a while (over 15 years!), and have now been incorporated into this deserving project. I am grateful that Don has allowed me to use such a great set of legs on my project!

I have made other tables, and they have also included marquetry and furniture skills, but this is an entirely different type of project I have embarked upon. This will be a first for many of the procedures and skills needed in order to complete this project. There will be 4 legs (my other projects only have 3), a single drawer which will be pulled from either side of the table to access the chess pieces, mortise and tenon joints and compartments inside the drawer for chess piece storage. I will post the progress and steps along the way to completing the American chess table, and also post the completed project in the gallery.

Cross your fingers, and hope this goes well!!

Initial lumber for the sides and drawer fronts (this is not the same maple we processed from north Georgia):

The lumber ripped for the drawer sides:

The actual drawer fronts are cut out of the lumber:

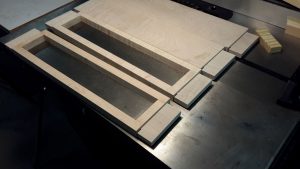

The drawer fronts are now glued together:

All four table sides are now processed by cutting tenons:

The legs are next!! See the next blog entry for details!